Factory Tour

What is a 48v Forklift Battery and How Does it Work?

The "48v Forklift Battery" is becoming a vital component in industrial operations. John Smith, a leading expert in battery technology, once said, "The efficiency of a 48v forklift battery can significantly enhance warehouse productivity." This statement encapsulates the importance of choosing the right battery for heavy lifting needs.

In recent years, the push for cleaner energy sources has led to increased focus on 48v forklift batteries. These batteries are designed to provide lasting power for electric forklifts, optimizing performance without harmful emissions. They stand out for their ability to deliver high voltage and power density, making them a preferred option for many businesses.

However, it’s essential to recognize certain downsides. Users must ensure proper maintenance to avoid performance drops. Additionally, the upfront cost can be daunting for small operations. Understanding the intricate dynamics of how the 48v forklift battery operates helps users make informed decisions. It's a balance between efficiency and investment that every warehouse manager must consider.

What is a 48v Forklift Battery?

A 48v forklift battery is a crucial power source for electric forklifts. It typically consists of multiple cells combined to achieve a voltage of 48 volts. These batteries are known for their efficiency and reliability. They provide the necessary energy to lift heavy loads and move them efficiently.

The design of a 48v forklift battery relies on advanced technology. This usually involves lead-acid or lithium-ion cells. Lead-acid batteries are more common for industrial use due to their durability. However, they can be heavy and require maintenance. Lithium-ion batteries, on the other hand, are lighter and require less upkeep. Yet, they often come with a higher initial cost.

Understanding how a 48v forklift battery works is essential. The battery stores electrical energy, converting it to power the forklift's motor. However, these batteries can become less efficient over time. Regular checks and maintenance are crucial to ensure they operate at peak performance. Not everyone realizes the importance of this upkeep. Neglecting battery care can lead to significant operational issues down the line.

48V Forklift Battery Performance Overview

This chart illustrates the performance metrics of a typical 48V forklift battery. It compares various aspects such as energy capacity, charging time, and average lifespan.

Components of a 48v Forklift Battery System

A 48v forklift battery system consists of several key components. The main part is the battery itself. These batteries typically utilize lead-acid or lithium-ion technology.

Lead-acid batteries are often less expensive but have a shorter lifespan.

Lithium-ion batteries, while pricier, can outlast lead-acid options by two to three times. According to industry reports, lithium-ion batteries can achieve up to 2,500 cycles, compared to just 1,000 cycles for lead-acid batteries.

Another essential component is the battery charger. The charger regulates the voltage and current going into the battery.

Improper charging can lead to reduced battery life. It's crucial for forklift operators to use chargers that match the specific battery type. This ensures efficiency and safety. The battery management system (BMS) is another vital element. A BMS monitors the battery's health and performance, protecting against overcharging and overheating.

There are risks associated with this system. Maintenance is often overlooked. Regular checks on connections and water levels in lead-acid batteries can prevent failures. In some cases, operators may notice diminished performance but procrastinate on assessing the issue. This can lead to more significant problems later. Understanding these components is crucial for an efficient and reliable forklift operation.

How a 48v Forklift Battery Generates Power

A 48v forklift battery is essential for powering electric forklifts in warehouses and manufacturing facilities. These batteries generate power through a process called electrochemical reactions. The battery consists of multiple cells, each producing about 2 volts. When linked together, they provide the necessary voltage for heavy-duty lifting tasks. A typical 48v battery setup includes 24 cells, combining their outputs to achieve optimal performance.

When a forklift is in operation, the battery supplies electrical energy. This stored energy powers the electric motor, enabling it to lift and move loads efficiently. Reports indicate that 48v forklift batteries can deliver up to 800 amp-hours, depending on the specific application. The efficiency can be impacted by various factors, including temperature and usage patterns.

However, there are challenges with 48v batteries. Battery degradation over time affects performance. Maintenance practices can sometimes be overlooked, leading to shorter lifespans. Inadequate charging cycles might lead to underperformance when demands are high. It's crucial to monitor battery health consistently to avoid potential inefficiencies. Understanding these nuances is vital to maximizing productivity in material handling operations.

Advantages of Using a 48v Forklift Battery

A 48v forklift battery is revolutionizing the material handling industry. It provides a balance of power and efficiency. These batteries are often used in electric forklifts to enhance performance. According to industry reports, a 48v system typically delivers around 50% more energy than a 24v system.

One key advantage of a 48v forklift battery is its ability to reduce overall operational costs. With lower energy consumption, businesses can see a decrease in electricity bills. Additionally, these batteries tend to have longer lifespans, often exceeding 1,500 charge cycles. This means less frequent replacements and lower maintenance expenses.

Another notable benefit is the faster charging time. Many users report that a 48v battery can be fully recharged in less than 8 hours. This can significantly reduce downtime. However, there's a catch. Not all facilities may have the infrastructure to support these charging systems. This could lead to unexpected challenges. Companies must assess their power supply capabilities before making the switch.

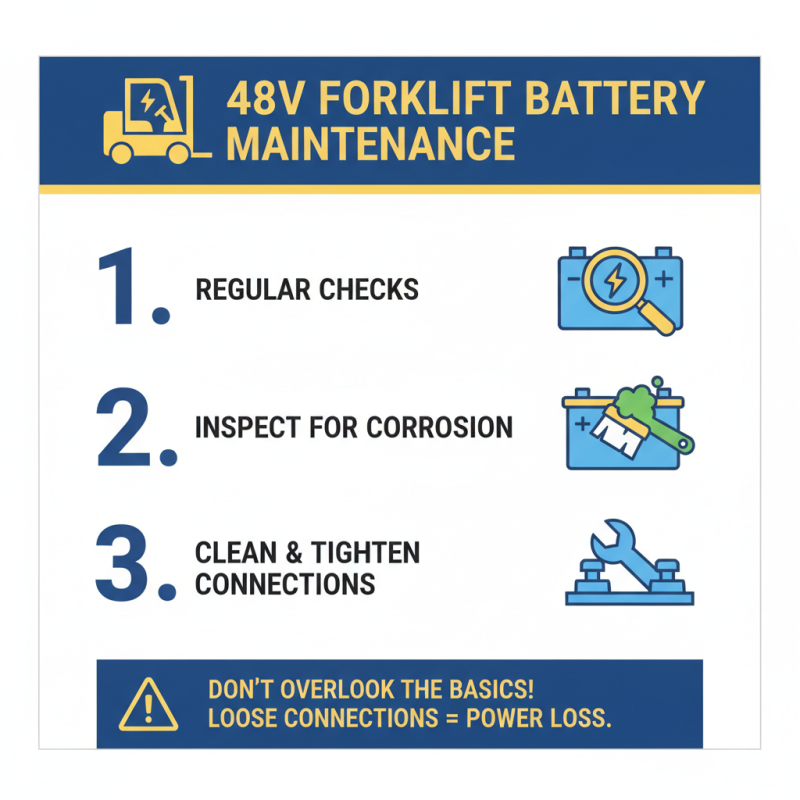

Maintenance and Best Practices for 48v Forklift Batteries

Maintaining a 48v forklift battery is crucial for optimal performance. Regular checks should be a part of the routine. Inspect the battery terminals for corrosion. Clean any build-up you find. Keep connections tight to ensure proper electrical flow. It's surprising how often these basics are overlooked. A loose connection can lead to significant power loss.

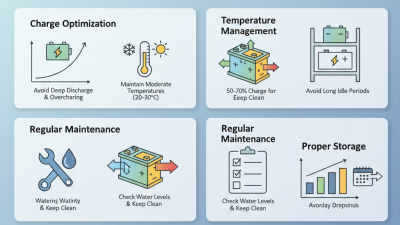

Battery watering is another key aspect. Under-filling can cause damage, while over-filling may lead to acid spills. Use distilled water for refills. This helps maintain battery health. Many users neglect this, thinking it’s not a big deal. However, consistent maintenance prolongs battery lifespan.

Charging practices also matter. Always charge at the right time. Avoid letting the battery fully discharge. This can harm its cells. Some may forget to check the charger settings, leading to inefficiencies. Take time to understand how your forklift battery works. Learning helps improve performance. Small details can make a big difference.

Related Posts

-

48v Forklift Battery Essential Tips for Optimal Performance and Longevity

-

Challenges Faced When Using 48v Forklift Batteries for Global Operations

-

How to Choose the Best 80v Forklift Battery for Your Business Needs

-

Future Trends in 2025 for the Best 48v Forklift Battery and Innovative Solutions for Sustainability

-

Chinese Excellence in Manufacturing the Best Power Wall Lifepo4 Battery 10kwh 200ah for Global Trust

-

7 Essential Forklift Battery Tips Every Global Buyer Should Know