Factory Tour

48v Forklift Battery Essential Tips for Optimal Performance and Longevity

The 48v Forklift Battery has become a cornerstone in the material handling industry, offering enhanced performance and efficiency for warehouse and logistics operations. As reported by industry experts, the demand for electric forklifts is projected to grow significantly, with expected market growth of over 7% annually through 2025. This shift towards electric solutions highlights the importance of optimizing the performance and longevity of essential components, such as the 48v Forklift Battery, to meet the increasing operational demands.

Understanding how to maintain and maximize the efficacy of the 48v Forklift Battery can lead to substantial cost savings and improved productivity. According to recent studies, properly managed battery systems can extend operational life by up to 30%, reducing downtime and replacement costs. This makes knowledge of essential battery maintenance tips not only valuable but crucial for business profitability. In this article, we will discuss essential strategies for optimizing the performance of the 48v Forklift Battery, focusing on best practices that ensure longevity and reliability in your material handling operations.

48V Forklift Battery Types: Overview of Options and Specifications

When considering the optimal use of 48V forklift batteries, it's crucial to understand the different types available and their specific capabilities. Broadly, there are two primary categories of 48V forklift batteries: lead-acid and lithium-ion. In the lead-acid category, conventional flooded batteries typically provide a lower upfront cost but require regular maintenance and watering. According to the Battery University, lead-acid batteries can last approximately 1,500 cycles under optimal conditions, making them a reliable choice for operations with less intensive use.

In contrast, lithium-ion batteries are rapidly gaining popularity due to their higher energy density and longer lifespan. They generally offer around 3,000 to 5,000 cycles, which can significantly reduce the cost of ownership over time. A report by the Industrial Truck Association indicates that the increased efficiency of lithium-ion batteries can improve operational productivity by 20% due to reduced downtime for battery changes or charging. This makes them particularly suitable for businesses operating in fast-paced environments where reliability and quick turnaround times are critical.

Understanding the nuances and specifications of these battery types allows companies to make informed decisions that not only enhance performance but also extend the lifespan of their forklifts. As the market continues to evolve, selecting the right type of battery to suit specific operational needs will play a pivotal role in achieving sustainability and efficiency in material handling operations.

Key Performance Metrics for 48V Forklift Batteries Explained

Understanding key performance metrics is crucial for optimizing the efficiency and lifespan of 48V forklift batteries. One of the primary metrics to consider is the state of charge (SOC), which indicates the current energy level of the battery. Maintaining the SOC within an optimal range not only ensures that the forklift operates at peak performance but also helps in preventing deep discharges that can lead to irreversible damage. Regular monitoring of SOC can aid operators in planning their charging cycles and ensuring that batteries are recharged before they reach critically low levels.

Another essential metric is the cycle life of the battery, which refers to the number of complete charge-discharge cycles a battery can undergo before its capacity significantly diminishes. This metric plays a vital role in operational cost-effectiveness, as higher cycle life means longer intervals before battery replacement. Operators should focus on practices that enhance cycle life, such as avoiding overcharging or using the battery in extreme temperature conditions. Monitoring battery temperature during operation can also provide insights into potential performance degradation and safety issues, allowing for timely interventions. By understanding and managing these performance metrics, operators can maximize the operational efficiency and longevity of their 48V forklift batteries.

48V Forklift Battery Performance Metrics

This chart displays the key performance metrics for 48V forklift batteries, highlighting the critical aspects that contribute to optimal performance and longevity. The data includes metrics such as discharge rate, cycle life, charging efficiency, and maintenance frequency.

Maintenance Best Practices for Prolonging Battery Life and Efficiency

Proper maintenance of a 48V forklift battery is critical for enhancing both its lifespan and operational efficiency. Regular inspection and maintenance can lead to a significant increase in battery life, often extending it by up to 30% according to industry research. Key best practices include regularly checking fluid levels, ensuring terminals are clean and tightly connected, and avoiding deep discharges. Studies show that batteries that are regularly monitored and maintained can achieve up to 80% of their rated cycle life, emphasizing the importance of proactive care.

Additionally, temperature regulation plays a crucial role in battery performance. Keeping batteries in a temperature-controlled environment can prevent premature degradation. Research indicates that for every 1°C rise in temperature above optimal levels, battery capacity can decrease by approximately 1.5%. Therefore, ensuring that your forklift batteries are stored and operated within a recommended temperature range is essential. Implementing a regular charging schedule and allowing proper cool-down periods between uses can further enhance battery health, ultimately leading to fewer operational interruptions and lower replacement costs.

48v Forklift Battery Essential Tips for Optimal Performance and Longevity

| Tip | Description | Frequency | Benefit |

|---|---|---|---|

| Regular Charging | Charge the battery after each shift to ensure full capacity. | After every use | Maximizes runtime and efficiency. |

| Water Levels | Check and refill water levels regularly to prevent cell damage. | Monthly | Prevents overheating and extends battery life. |

| Clean Terminals | Ensure battery terminals are free from corrosion. | Quarterly | Improves electrical connectivity and performance. |

| Temperature Control | Store batteries in a temperature-controlled environment. | As needed | Prevents capacity loss and ensures optimal performance. |

| Load Testing | Perform load tests to evaluate battery health. | Annually | Identifies weak cells that may need replacement. |

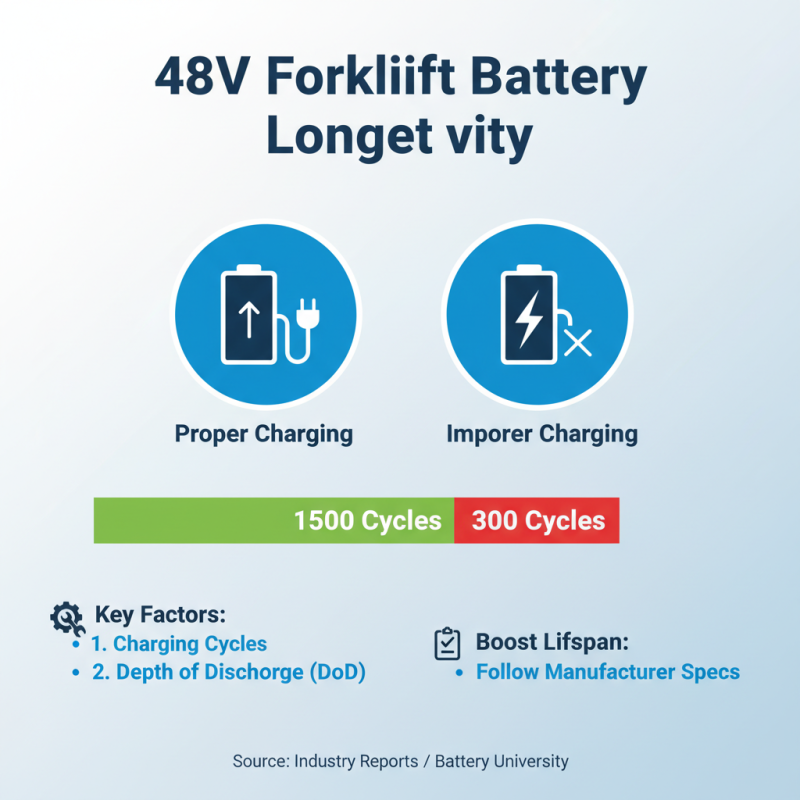

The Importance of Charging Cycles and Depth of Discharge for Longevity

The longevity and performance of a 48V forklift battery heavily depend on two critical factors: charging cycles and the depth of discharge (DoD). According to industry reports, maintaining optimal charging practices can significantly enhance battery life. A study by the Battery University indicates that a lead-acid forklift battery, for instance, can achieve up to 1,500 cycles when properly charged, compared to merely 300 cycles if charged improperly. This underlines the importance of adhering to manufacturers' recommendations on charging frequency and duration to ensure batteries meet their lifespan potential.

Moreover, the depth of discharge is a pivotal element in battery maintenance. Research suggests that limiting DoD to 50% can nearly double the overall lifespan of a battery. For example, regularly discharging a battery to 70% of its capacity can lead to premature aging and diminished performance. To maximize efficiency, operators should aim to recharge batteries when they reach around 20-30% of their capacity, which not only safeguards the battery’s health but also optimizes the operational workflow in high-demand environments.

Tip 1: Always utilize the appropriate charging method to suit the battery type, reducing overheating risks and prolonging its life.

Tip 2: Establish a routine to monitor charge levels, ensuring that your teams are aware of optimal discharge limits to maintain battery health.

By understanding and implementing these practices, operators can significantly improve the operational efficiency and lifespan of their 48V forklift batteries.

Safety Guidelines and Best Practices for Handling Forklift Batteries

When handling 48v forklift batteries, safety should always be the top priority. Ensure that you are equipped with appropriate personal protective equipment (PPE), such as gloves, safety goggles, and face shields, to protect against potential acid spills and electrical hazards. Additionally, it's crucial to inspect the battery regularly for any signs of damage, leaks, or corrosion, which can pose risks during operation. A clean and well-ventilated environment is vital, as it prevents the buildup of explosive gases that can occur during charging.

Best practices for handling these batteries extend beyond just personal safety. It’s essential to utilize proper lifting techniques and equipment when moving forklift batteries to avoid injuries. Always ensure that the battery is disconnected before performing any maintenance work, and follow correct procedures for charging and discharging. Familiarizing yourself with emergency protocols in case of battery failure or accidents is equally important. By adhering to these safety guidelines and best practices, you can maximize the longevity and performance of your forklift battery while minimizing the risk of accidents in the workplace.

Related Posts

-

Challenges Faced When Using 48v Forklift Batteries for Global Operations

-

Future Trends in 2025 for the Best 48v Forklift Battery and Innovative Solutions for Sustainability

-

Precision Engineering in China Elevates the Best 48v 300ah Forklift Battery for Global Service

-

Essential Forklift Battery Maintenance Checklist for Optimal Performance

-

Exploring Innovative Alternatives for 80v Forklift Battery Solutions

-

How to Choose the Right Forklift Battery for Optimal Performance and Longevity