Factory Tour

Top 5 Benefits of Using a 48V 300Ah Forklift Battery in 2025

As the material handling landscape evolves in 2025, the demand for efficient and sustainable energy solutions in warehouse operations is at an all-time high. Among the various innovations in industrial battery technology, the 48V 300Ah Forklift Battery stands out as a formidable choice for businesses looking to enhance their operational efficiency. Reports indicate that the use of advanced battery systems can lead to a 25% reduction in energy costs, supporting increased productivity and sustainability in warehouse environments.

In recent years, the logistics and manufacturing sectors have seen a rising preference for electric forklifts, with an estimated 40% of operations transitioning from traditional fuel-based solutions to electric-powered ones by 2025. This shift is driven by the growing emphasis on reducing carbon footprints and optimizing energy consumption. The 48V 300Ah Forklift Battery not only offers significant performance benefits—such as increased run time and faster charging—but it also aligns with the industry's move towards greener technologies, as electric forklifts can reduce greenhouse gas emissions by up to 60% compared to their gas or diesel counterparts.

The implementation of the 48V 300Ah Forklift Battery promises not only to enhance the capabilities of electric forklifts but also fosters a smarter, more efficient approach to material handling. As the need for reliability and performance in industrial operations continues to grow, this advanced battery technology is poised to transform the landscape of material handling equipment well into the next decade.

Advantages of Higher Voltage in Forklift Batteries

The advantages of using a 48V 300Ah forklift battery are particularly noticeable in the context of higher voltage systems. One of the primary benefits is improved efficiency. A higher voltage system allows for better energy transfer, reducing the overall current required. This results in less heat generation and minimizes energy loss during operation, ultimately enhancing the battery’s lifespan and performance.

Moreover, higher voltage enables increased power output without the need for oversized cables and connections. This means manufacturers can design more compact and lighter forklift systems, which is particularly beneficial in warehouses with tight spaces. As a tip, businesses should consider the specific power requirements of their operations to ensure they choose the right battery system that maximizes both efficiency and performance.

Another key advantage is faster charging times. High-voltage batteries typically recharge more quickly, which translates to less downtime and greater productivity. When selecting a forklift battery, it’s essential to evaluate the charging infrastructure to fully utilize the rapid recharging capabilities that a 48V system provides. Remember to align battery voltage with your forklift model to ensure compatibility and optimal performance.

Top 5 Benefits of Using a 48V 300Ah Forklift Battery in 2025

| Benefit | Description | Impact on Efficiency | Cost Savings |

|---|---|---|---|

| Increased Power | Higher voltage provides more power for demanding applications. | Significantly improves lifting and hauling capabilities. | Reduces operational time, leading to lower labor costs. |

| Longer Runtime | 300Ah capacity allows for extended use without frequent recharging. | Increases operational hours per shift. | Minimizes downtime and battery replacement costs. |

| Faster Charging | Higher voltage systems can charge more quickly. | Reduces time spent in charging stations. | Shortens maintenance and overall operational costs. |

| Better Performance in Cold | Higher voltage batteries perform better in low temperatures. | Maintains efficiency in challenging environments. | Less need for additional heating equipment. |

| Enhanced Safety Features | Modern designs include safety features to prevent overheating. | Decreases risk of accidents related to battery failures. | Lowers insurance and liability costs. |

Enhanced Efficiency and Performance of 48V 300Ah Batteries

In 2025, the adoption of 48V 300Ah forklift batteries offers significant advantages in enhancing efficiency and performance, particularly in settings where energy reliability is critical. These batteries are designed to provide a consistent and powerful energy output, essential for operations that demand heavy lifting and long hours of use. With an increase in operational efficiency reported to be as high as 20%, businesses can experience reduced downtime and improved productivity, thus maximizing their overall output.

The performance characteristics of 48V 300Ah batteries lie in their sophisticated design, which allows for faster charging and longer usage times. Reports indicate that these advanced batteries can reduce charging cycles by up to 30%, minimizing energy costs and enhancing workflow in warehouse and manufacturing environments. Furthermore, in regions like Nigeria, where energy efficiency is paramount due to frequent power outages and rising electricity prices, integrating these robust forklift batteries can significantly mitigate operational challenges, thus empowering businesses to maintain competitiveness in a fluctuating market.

Longer Service Life and Lower Maintenance Needs

The use of a 48V 300Ah forklift battery in 2025 comes with a range of advantages, particularly in terms of service life and maintenance requirements. These advanced batteries are designed to last significantly longer than their predecessors, thanks to improved technology and materials. This longevity not only reduces the frequency of replacements but also translates into decreased operational downtime, allowing businesses to maintain productivity levels.

Moreover, lower maintenance needs are a major benefit of the 48V 300Ah forklift batteries. With fewer components that require regular checks and upkeep, the overall workload on maintenance teams is minimized. This efficiency can lead to substantial cost savings, as businesses can allocate resources more effectively. Moreover, the simplified maintenance process ensures that issues can be addressed quickly, enhancing the reliability of forklift operations in demanding environments. By investing in these batteries, companies can ensure seamless and efficient performance while reducing the associated maintenance burdens.

Environmental Benefits of Using 48V Battery Technology

The adoption of 48V battery technology in forklifts offers significant environmental benefits that are increasingly vital in today's industrial landscape. One of the primary advantages is the reduction in greenhouse gas emissions. Unlike traditional internal combustion engines, 48V electric forklift batteries produce zero tailpipe emissions, contributing to cleaner air quality in warehouses and distribution centers. This shift not only helps meet regulatory requirements but also aligns with corporate sustainability goals, fostering a greener image for businesses.

Additionally, 48V battery systems are generally more efficient than their higher voltage counterparts, leading to reduced energy consumption over time. By optimizing power usage, companies can minimize their carbon footprint while also lowering utility costs. Furthermore, the use of recyclable materials in the manufacturing of these batteries enhances their eco-friendliness, as it promotes a circular economy. By investing in 48V technology, businesses can play a crucial role in promoting environmental stewardship and sustainable practices within their operations.

Cost Savings Over Time with Efficient Forklift Battery Systems

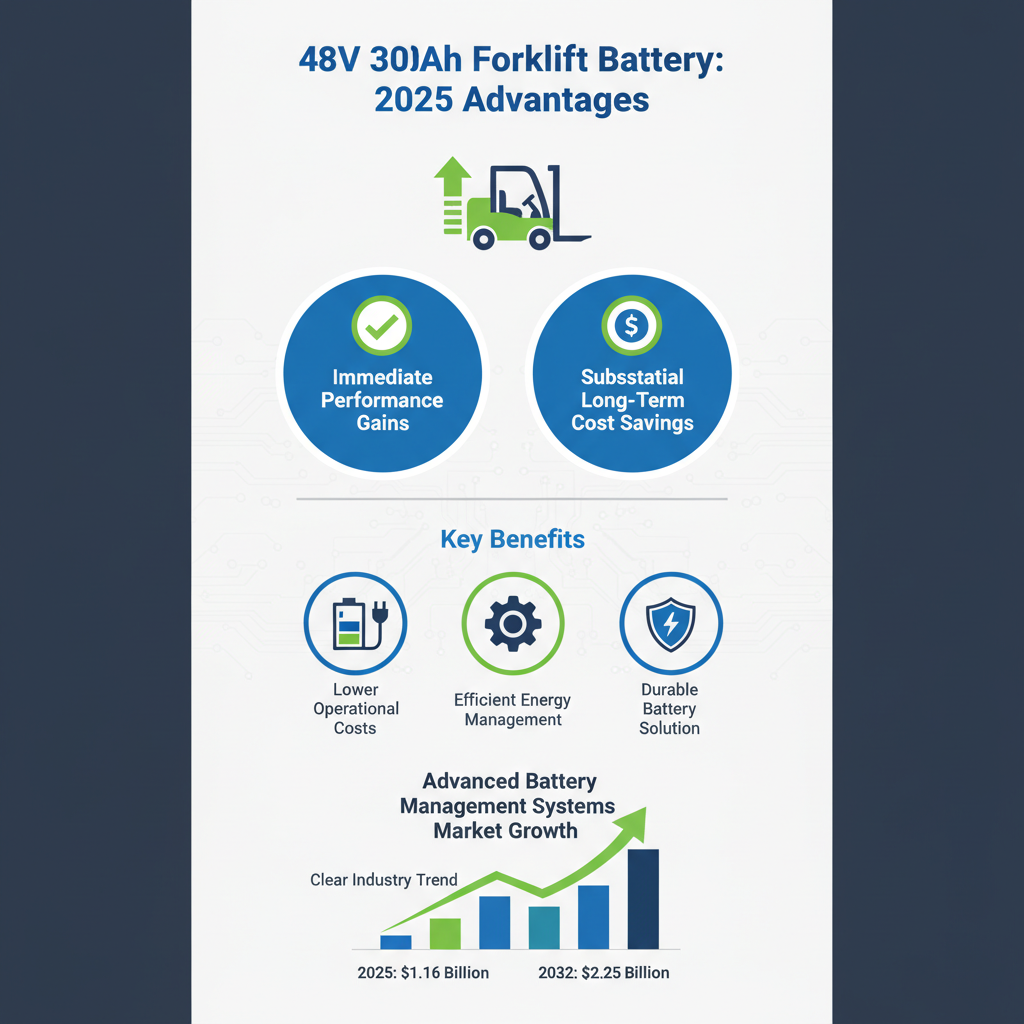

The advantages of utilizing a 48V 300Ah forklift battery in 2025 extend beyond immediate performance gains to substantial long-term cost savings. As enterprises increasingly adopt electric forklifts, the shift towards efficient battery systems directly correlates with lower operational costs. Advanced battery management systems are gaining traction, projected to burgeon from $1.16 billion in 2025 to $2.25 billion by 2032, indicating a clear industry trend towards improved energy management and investment in durable battery solutions.

Cost efficiency is further enhanced by integrating AI technologies to optimize battery performance and sustainability. AI applications in energy trading, safety monitoring, and predictive analytics facilitate better resource allocation and reduce downtime, ultimately translating to decreased expenses for businesses relying on forklift operations. As such, leveraging a 48V 300Ah battery not only meets the rising demand for reliable power sources in industrial settings but also represents a strategic move towards achieving long-term financial viability in an increasingly competitive market.

Related Posts

-

Challenges Faced When Using 48v Forklift Batteries for Global Operations

-

Future Trends in 2025 for the Best 48v Forklift Battery and Innovative Solutions for Sustainability

-

How to Maximize the Lifespan of Your Forklift Battery

-

Maximizing Efficiency: The Ultimate Guide to 48V 300Ah Forklift Batteries for Modern Warehousing

-

Unlocking the Power of Auto Lifepo4 Start Batteries: A Deep Dive into Their Advantages and Features

-

What Makes Power Wall Lifepo4 Battery 10kwh 200ah a Game Changer in Energy Storage