Factory Tour

Why Is Choosing the Right Forklift Battery Important for Your Business?

Choosing the right forklift battery is crucial for operational efficiency. According to a recent report by the Battery Council International, improper battery selection can lead to a 20% decrease in overall productivity. This is significant in an industry where every minute counts. The right forklift battery not only affects performance but also impacts safety and maintenance costs.

As expert David Thompson, a well-respected authority in the forklift battery sector, states, "A reliable battery can make or break your warehouse operation." The logistics and warehouse environments require robust and efficient energy solutions. Battery failure can lead to unexpected downtime and increased operational expenses.

Many businesses still overlook factors such as battery life and charging capabilities. This oversight can result in underperformance. With an increasing demand for efficiency, understanding the nuances of forklift batteries is more important than ever. Ignoring these considerations could mean the difference between profit and loss.

Importance of Forklift Batteries in Material Handling Operations

Forklift batteries play a crucial role in material handling operations. They are the power source for these machines, which are essential in warehouses and manufacturing. A reliable battery ensures that forklifts operate smoothly and efficiently. If the battery fails, it can halt productivity, leading to costly delays. Many businesses overlook this aspect, focusing instead on other equipment.

Choosing the right battery type can significantly impact performance. Different operations require varying power levels and run times. A warehouse that runs multiple shifts needs a high-capacity battery. In contrast, a facility with intermittent use may not require as powerful a source. Understanding your operational needs is vital. It’s easy to underestimate the importance of proper maintenance too. Neglecting battery care results in shortened lifespan and potential damage.

Additionally, battery choices reflect on overall operational costs. Higher-quality batteries might have a higher upfront cost but can result in long-term savings. They often require less frequent replacement, reducing waste and maintenance expenses. It's important to evaluate long-term benefits alongside initial investment. Many decisions are made without adequate research, leading to regrets later. That comes at the expense of efficiency and profitability.

Key Factors in Selecting the Right Forklift Battery for Your Needs

Choosing the right forklift battery is critical. It directly impacts your warehouse efficiency and operational costs. Different types of batteries are designed for various applications, from lead-acid to lithium-ion. Each option has unique characteristics that can affect performance and lifespan. According to a recent industry report, batteries make up around 20% of a forklift's total lifetime cost.

When selecting a battery, consider the duty cycle. Analyze how often the forklift operates during the day. A battery that cannot handle frequent use will lead to downtime. Downtime translates to lost productivity. Additionally, the environment plays a role. Temperature and humidity can affect battery life and performance. In colder conditions, lead-acid batteries may lose 30% of their efficiency.

Another crucial factor is maintenance. Some batteries require regular water refills, while others do not. Lithium-ion batteries need less maintenance, but their upfront cost is higher. The choice between cost and convenience can be challenging. Balancing these factors is essential for long-term success. Ensuring the battery fits your specific needs may prevent issues down the line.

Comparing Different Types of Forklift Batteries: Pros and Cons

Choosing the right forklift battery is crucial for operational efficiency. Different types of batteries have unique characteristics that influence performance. Lead-acid batteries are common. They are lower in initial cost and well-known. However, they require more maintenance and have a shorter lifespan—about 1,500 cycles on average. In busy warehouses, this can hinder productivity.

On the other hand, lithium-ion batteries are gaining popularity. These batteries have longer lifespans, around 3,000 to 5,000 cycles. They charge faster and often require less maintenance. However, their upfront costs are higher. Some companies report a 30% increase in productivity with lithium-ion batteries due to less downtime. Still, many businesses hesitate to invest upfront.

Choosing the right battery type impacts your bottom line. According to recent industry reports, businesses can save up to 20% on energy costs by selecting the proper battery. This potential savings may outweigh initial costs. However, organizations must evaluate their operational needs carefully. What works for one may not suit another well.

Comparison of Different Types of Forklift Batteries

This chart compares the main types of forklift batteries based on their overall pros and cons score. The scores reflect factors like efficiency, lifespan, maintenance, and cost-effectiveness.

Impact of Forklift Battery Lifespan on Business Efficiency and Costs

Choosing the right forklift battery significantly affects your business's efficiency and operational costs. A quality battery can improve productivity, reduce downtime, and lower overall expenses. Studies show that a robust battery can extend a forklift’s lifespan by up to 30%. This, in turn, leads to fewer replacements and repairs, saving businesses thousands of dollars annually.

However, many companies underestimate the importance of battery maintenance. A neglected battery can lose its efficiency quickly. In fact, a typical lead-acid battery can lose up to 25% of its capacity without proper care. This loss directly impacts the phone's performance, leading to slower operations and reduced lifting power. Research indicates that over 50% of businesses experience costly delays due to battery-related issues.

The lifespan of a forklift battery is vital. According to industry reports, batteries that are routinely serviced can last 1,500 to 2,000 cycles. Conversely, a poorly maintained battery may barely reach 1,000 cycles. The difference in lifespan directly correlates to higher costs and inefficiencies. This situation forces many companies to re-evaluate their battery management strategies and practices.

Why Is Choosing the Right Forklift Battery Important for Your Business? - Impact of Forklift Battery Lifespan on Business Efficiency and Costs

| Battery Type | Average Lifespan (Years) | Estimated Cost ($) | Maintenance Frequency (Months) | Impact on Efficiency (%) |

|---|---|---|---|---|

| Lead Acid | 3-5 | 1,500 | 6 | 20 |

| Lithium-Ion | 5-8 | 3,000 | 12 | 30 |

| Nickel Cadmium | 4-7 | 2,000 | 8 | 25 |

| Gel Cell | 5-7 | 2,500 | 10 | 15 |

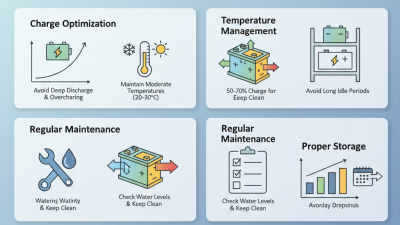

Best Practices for Maintaining Forklift Batteries for Optimal Performance

Maintaining forklift batteries is crucial for ensuring optimal performance in any warehouse. A well-maintained battery can improve a forklift's efficiency by up to 30%. This efficiency translates to increased productivity and reduced operational costs. Regular maintenance includes checking electrolyte levels and ensuring clean terminals. Neglecting these tasks can lead to battery failure, costing businesses significant downtime.

Charging practices also play a vital role. Batteries should be charged regularly, ideally after each shift. A study showed that improperly charged batteries can decrease lifespan by over 20%. Employees must understand the importance of this routine. Monitoring temperature during charging is essential. Heat can damage the battery's internal components, leading to unstable performance.

Training staff in battery care is often overlooked. A survey found that 40% of workers lack basic knowledge about battery maintenance. This gap can lead to misunderstandings and, ultimately, higher costs. Companies should invest in training programs. Knowledgeable workers are key to maximizing battery life and performance. Small adjustments can lead to big improvements.

Related Posts

-

How to Maximize the Lifespan of Your Forklift Battery

-

Essential Forklift Battery Maintenance Checklist for Optimal Performance

-

How to Choose the Right Forklift Battery for Optimal Performance and Longevity

-

48v Forklift Battery Essential Tips for Optimal Performance and Longevity

-

7 Best Insights on 16s Lfp Boat Battery for Global Buyers

-

How to Choose the Right 72V LiFePO4 Battery for Your Golf Cart: Essential Insights and Tips