Factory Tour

Top Strategies for Maximizing Efficiency with 80v Forklift Battery Technology

As industries strive for enhanced productivity and reduced operational costs, the adoption of advanced technologies has become crucial. Among these innovations, the 80v Forklift Battery stands out as a pivotal element in optimizing warehouse efficiency and logistics operations. According to the latest report from the Industrial Truck Association, the adoption of high-voltage battery systems can increase energy efficiency by up to 30% compared to traditional 36v and 48v systems. This significant improvement directly translates to reduced charging times and extended operational hours, allowing businesses to streamline their processes. Moreover, with enhanced power density and greater lift capabilities, 80v Forklift Batteries are poised to transform modern material handling. In this guide, we will explore the top strategies for maximizing efficiency with this cutting-edge battery technology, helping organizations harness its full potential.

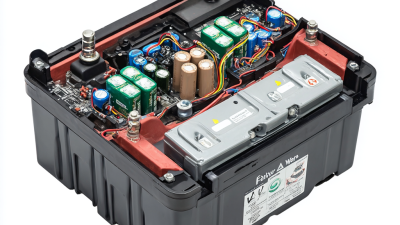

Understanding 80v Forklift Battery Technology: Key Features and Benefits

Understanding 80v forklift battery technology reveals a plethora of key features and benefits that significantly enhance operational efficiency. The high voltage of 80v batteries allows for greater power output, making them particularly suitable for heavy-duty applications. With the capability to sustain intensive operations across multiple shifts, these batteries are essential for businesses that require constant performance and minimal downtime. In addition, advancements in battery management technologies ensure that charging is optimized, further reducing operational costs and improving overall sustainability.

Moreover, the evolution of 80v electric forklifts showcases the commitment to innovation within material handling solutions. These forklifts are designed not just for power, but also for functionality and ergonomic benefits, which can lead to increased productivity. The recent implementation of lithium-ion batteries offers advantages such as faster charging times and a longer lifespan, making them a sound investment for warehouses and distribution centers. The incorporation of repurposed batteries into energy solutions highlights a growing trend towards sustainable practices in the industry, ensuring that the benefits of 80v technology extend beyond initial use and contribute positively to environmental efforts.

Comparative Analysis: 80v Forklifts vs. Traditional Battery Systems

The forklift truck market has seen a significant evolution with the introduction of 80V battery systems, which offer numerous advantages over traditional battery systems. These high-voltage batteries deliver increased power and efficiency, making them suitable for demanding material handling environments.

Compared to standard battery options, 80V systems provide longer run times and shorter charging cycles, allowing businesses to maximize productivity and minimize downtime. This efficiency translates into lower operating costs, which is crucial for industries relying heavily on forklifts for their operations.

Compared to standard battery options, 80V systems provide longer run times and shorter charging cycles, allowing businesses to maximize productivity and minimize downtime. This efficiency translates into lower operating costs, which is crucial for industries relying heavily on forklifts for their operations.

Additionally, the environmental impact of battery technology cannot be overlooked. The ability to recycle end-of-life lithium batteries from forklifts into solar energy storage solutions exemplifies the sustainable practices emerging in the industry. This not only extends the lifecycle of these batteries but also supports renewable energy initiatives, creating a win-win situation for businesses and the planet. As industries increasingly prioritize sustainability, the shift towards 80V forklift systems represents a smart and responsible investment in both efficiency and environmental stewardship.

Maximizing Efficiency: Best Practices for Operating 80v Forklift Batteries

In the world of material handling, maximizing efficiency with 80V forklift batteries is crucial for maintaining productivity and reducing operational costs. With advancements in battery technology, operators can harness the full potential of their forklifts while ensuring that they are maximizing uptime. Adopting best practices for operating these batteries can lead to significant improvements in performance and longevity.

One essential tip for enhancing battery efficiency is to regularly monitor the state of charge. Keeping an eye on the battery's charge level can prevent unnecessary downtime caused by unexpected depletions. Additionally, utilizing scheduled charging cycles during non-peak hours can extend battery life, as high charging frequency can lead to overheating and reduce capacity over time.

Another best practice is to ensure optimal maintenance of the forklift equipment. Conducting routine inspections and addressing any mechanical issues promptly can prevent excessive strain on the battery, thereby prolonging its lifespan. It’s also beneficial to train staff on efficient operating techniques, such as smooth acceleration and deceleration, which can significantly reduce energy consumption and improve overall battery performance. By implementing these strategies, operators can achieve a seamless and efficient operation while leveraging the latest in battery technology.

Top Strategies for Maximizing Efficiency with 80v Forklift Battery Technology

| Strategy | Description | Expected Benefits | Implementation Tips |

|---|---|---|---|

| Regular Maintenance | Routine inspections and maintenance of battery and forklift | Increased lifespan and reliability of equipment | Schedule monthly check-ups; keep a maintenance log |

| Optimal Charging Practices | Ensuring batteries are charged appropriately | Maximized efficiency and battery life | Use smart chargers and avoid overcharging |

| Proper Storage Conditions | Storing batteries in an optimal environment | Enhanced performance and safety | Keep batteries in a dry, temperature-controlled space |

| Staff Training | Training operators on best handling practices | Increased safety and efficiency | Conduct regular training sessions and updates |

| Battery Management System | Using a system to monitor battery usage and health | Prolonged battery life and optimized usage | Integrate a BMS with your fleet management software |

Routine Maintenance Tips for Extending the Life of Your 80v Forklift Battery

Routine maintenance is crucial for extending the life of your 80V forklift battery. Regularly check the battery terminals for corrosion and ensure they are clean and tight. A clean connection minimizes resistance, which can improve performance and extend the longevity of the battery. Additionally, it's advisable to inspect the battery fluid levels and top them off with distilled water as needed. Avoid overcharging, as this can lead to premature wear and reduced efficiency.

Another important aspect of maintenance is monitoring the battery's temperature. Excessive heat can shorten battery life, so ensure that the charging area is well-ventilated. When storing your forklift, ensure that the battery is kept in a cool, dry environment. Implementing these simple maintenance practices can significantly enhance the performance and lifespan of your 80V forklift battery.

With the recent introduction of a new 80V lithium-ion battery range designed for airport ground support equipment, it's evident that innovations in battery technology are paving the way for better efficiency and reliability. Utilizing these advancements alongside proper maintenance strategies will ensure that your operations run smoothly and effectively.

Cost-Benefit Breakdown: Investing in 80v Forklift Technology for Your Business

Investing in 80v forklift battery technology can lead to significant cost savings and operational efficiency for businesses. As companies strive to meet decarbonization targets, implementing efficient logistics solutions becomes crucial. An effective 80v forklift system not only reduces emissions but also minimizes energy costs, paving the way for a sustainable future. By optimizing battery performance, businesses can experience longer operational hours and decreased downtime, further enhancing productivity.

**Tip 1:** Regularly assess your forklift fleet’s performance data to identify areas where energy consumption can be minimized. This proactive approach helps you stay ahead of maintenance needs and prevents unexpected costs.

**Tip 2:** Consider integrating automated solutions into your material handling process. Advanced technologies can streamline operations, reduce labor costs, and improve overall efficiency, making the initial investment in 80v technology even more advantageous.

Prioritizing a robust maintenance program is essential for maximizing the benefits of 80v forklift technology. Scheduled maintenance not only prolongs the lifespan of your equipment but also ensures that your fleet operates at peak efficiency. By investing wisely in the right technologies, you can enhance your business’s competitiveness and contribute to a greener logistics industry.

Maximizing Efficiency with 80v Forklift Battery Technology

This chart represents a cost-benefit analysis concerning the investment in 80v forklift battery technology. It illustrates the initial investment, annual maintenance costs, operational efficiency returns, and potential energy cost savings, showing how these factors influence the overall efficiency of your business operations.

Related Posts

-

The Future of High Performance Golf Cart Batteries Powered by 48v Lifepo4 Technology

-

Crafted Excellence: The Global Rise of China's Premier Wall-Mounted Energy Storage Solutions

-

How to Save on Repair Costs with Exceptional After Sales Service for Best 72v Golf Cart Battery

-

Explore Reliable Quality: The Best 72v Golf Cart Battery from China for Global Buyers

-

Precision Engineering in China Elevates the Best 48v 300ah Forklift Battery for Global Service

-

7 Best Features of 80v Forklift Battery That Will Maximize Your Warehouse Efficiency