Factory Tour

2026 Top Automobile Start Lithium Battery Innovations Explained

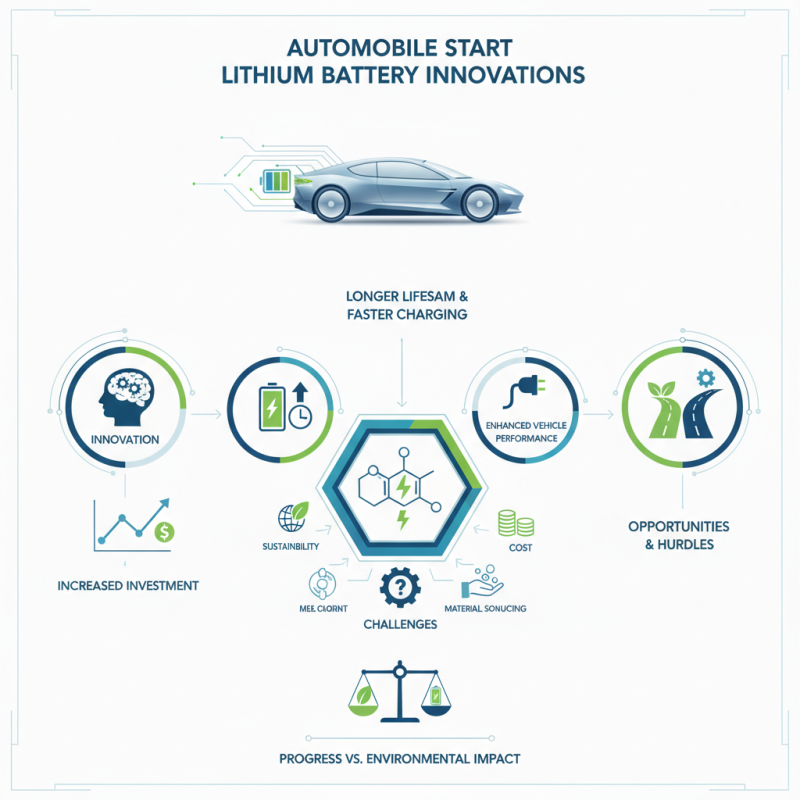

The automotive industry is rapidly evolving, and one of the most exciting developments is in Automobile Start Lithium Battery technology. Experts like Dr. Emily Carter, a leading researcher in battery innovations, emphasize the potential of these batteries. She once stated, "The future of sustainable transport lies in our ability to innovate battery technology."

In recent years, the demand for more efficient and reliable batteries has surged. Automobile manufacturers are increasingly investing in lithium batteries to enhance vehicle performance. These advancements promise longer life spans and faster charging times, yet challenges remain. Issues such as cost and material sourcing must be addressed to ensure widespread adoption.

While innovation is crucial, it is also important to reflect on the impact of these developments. Many people are unaware of the environmental implications of battery production. Finding a balance between progress and sustainability will be essential. The road ahead for Automobile Start Lithium Batteries is filled with opportunities but also significant hurdles to overcome.

Overview of Lithium Battery Technology in the Automobile Industry

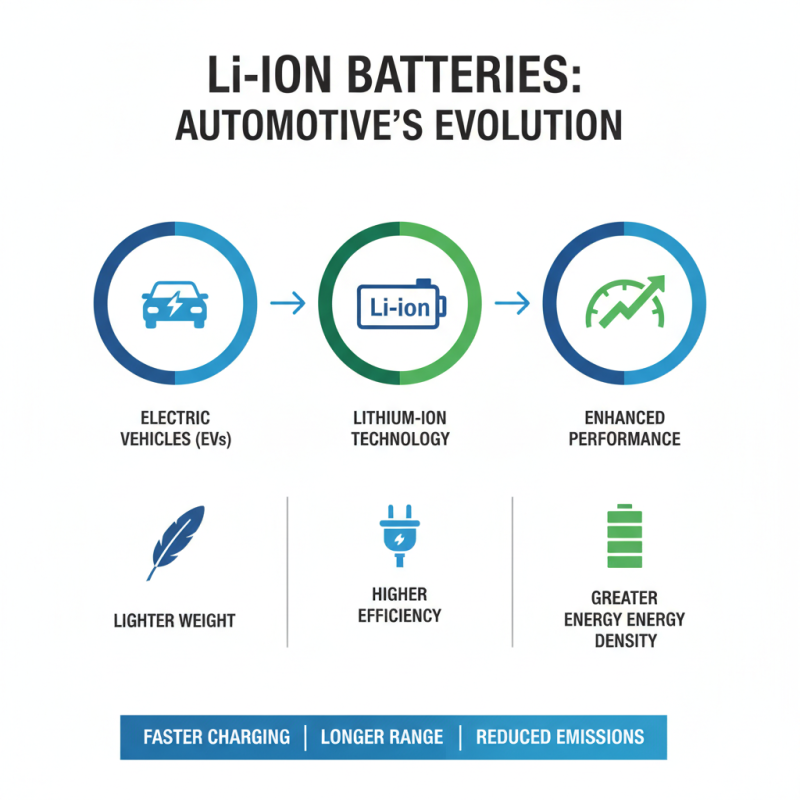

Lithium battery technology is rapidly evolving in the automobile industry. These batteries are lighter, more efficient, and offer greater energy density than traditional options. This makes them ideal for electric vehicles (EVs). The automotive sector is increasingly relying on these batteries to enhance performance and reduce emissions.

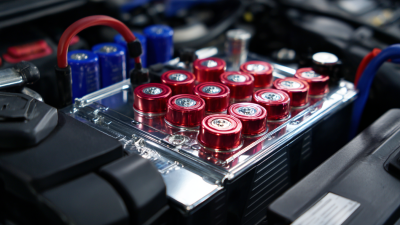

Battery management systems play a crucial role in optimizing the performance of lithium batteries. They monitor temperature, charge levels, and overall health. This ensures that the batteries operate safely and efficiently. However, these systems can sometimes be complex. This complexity may lead to errors that affect performance. Regular updates and maintenance are vital.

Tip: Always check your battery’s health. A neglected battery can reduce vehicle performance.

Moreover, recycling lithium batteries is becoming a significant challenge. As demand grows, so does waste. Improper disposal could lead to environmental issues. Innovative recycling methods are essential to mitigate these concerns.

Tip: Stay informed about recycling programs in your area. Participating can help reduce your carbon footprint and contribute to sustainability.

Finding a balance between performance and safety remains a key goal. The industry faces challenges but is committed to advancements in battery technology. The future of automotive lithium batteries looks promising, but there are still hurdles to overcome.

Key Innovations in Lithium Battery Chemistry for Electric Vehicles

The electric vehicle (EV) market is evolving rapidly. Innovations in lithium battery chemistry are at the forefront of this change. Industry reports indicate that lithium-ion batteries still dominate the market, accounting for over 80% of EV battery sales. However, advancements like solid-state batteries are gaining momentum. These batteries promise higher energy density and improved safety. They could potentially offer 300 miles or more on a single charge.

Another key area of innovation is in battery recycling. Reports suggest that less than 5% of lithium-ion batteries are currently recycled effectively. This poses a significant challenge as demand for battery materials increases. Advanced recycling techniques are being developed that can recover up to 95% of lithium, cobalt, and nickel from old batteries. This not only reduces waste but also addresses material shortages.

Research into new battery chemistries is ongoing. Sodium-ion and lithium-sulfur batteries are emerging as potential alternatives. They may provide lower costs and enhanced performance. Yet, these technologies still face hurdles before they can be commercially viable. The balance between performance, cost, and environmental impact requires careful consideration. The future of lithium batteries in EVs is bright, but much work remains to be done.

Advancements in Battery Manufacturing Processes for 2026 Models

As we approach 2026, the automobile industry is seeing remarkable advancements in lithium battery manufacturing. Companies are exploring new materials that enhance energy density and charging speed. These materials aim to improve overall battery performance while reducing costs. With the push for sustainability, recycling methods are also being refined. This can give new life to old batteries, which is a step towards a circular economy.

Innovations in production processes are equally significant. High-throughput manufacturing techniques are being adopted. These techniques allow for quicker assembly and better quality control. It's fascinating, yet some challenges remain. The balance between speed and precision can be difficult to achieve. Mistakes in the process can lead to defects, which may affect performance later on.

Enhanced safety measures are being put into place as well. The risk of lithium-ion batteries catching fire cannot be overlooked. New thermal management systems are being developed to address this issue. However, there is still much to learn about long-term safety and durability. Engineers must keep refining these systems to ensure consumer confidence. The future of automobile batteries is bright, but it requires continual improvement and reflection.

2026 Top Automobile Lithium Battery Innovations

This chart illustrates the advancements in lithium battery manufacturing processes for 2026 automobile models. The data includes different innovations and their corresponding energy densities measured in Wh/kg.

Impact of Lithium Battery Innovations on Vehicle Performance and Range

Lithium battery innovations are transforming the landscape of automobile performance and range. These advancements significantly improve energy density and charging speeds. Drivers now expect more from their vehicles. A robust battery means longer trips without frequent stops for charging.

Recent developments showcase lighter battery designs and enhanced thermal management systems. Such systems help maintain optimal operating temperatures. However, some challenges remain. Augmented energy density could lead to potential overheating issues. Balancing performance with safety is critical. Innovations must address these concerns to ensure reliability.

Moreover, the infrastructure for charging needs improvement. Fast-charging stations are limited in some regions. This affects overall convenience for drivers. Battery technology might advance quickly, but real-world applications take longer. Addressing these issues is vital for the broader acceptance of electric vehicles.

Future Trends and Challenges in Lithium Battery Development for Automobiles

The landscape of lithium battery development for automobiles is evolving rapidly. As manufacturers strive for better performance, several significant trends are emerging. Increased energy density is one of the most critical focuses. Engineers are experimenting with new materials that promise to store more energy while remaining lightweight. This change could lead to longer ranges for electric vehicles, making them more appealing to mainstream consumers.

However, these advancements come with challenges. Supply chain issues can hinder access to essential materials. Additionally, safety concerns regarding battery fires remain prevalent. Innovations must address these risks without sacrificing performance. The industry needs to balance efficiency with safety.

Sustainability is another major concern. The environmental impact of lithium extraction is significant. As demand grows, so does the need for sustainable practices. Future innovations must prioritize recycling and reducing waste. This is not just a technical challenge; it requires a change in mindset across the industry. The path forward is not straightforward, but the potential benefits are immense.

2026 Top Automobile Start Lithium Battery Innovations Explained

| Innovation Type | Key Features | Advantages | Challenges | Projected Impact |

|---|---|---|---|---|

| Solid-State Batteries | Higher energy density, improved safety. | Longer range, reduced risk of fire. | Manufacturing challenges, cost issues. | Greater vehicle efficiency, longer lifespans. |

| Recycling Technologies | Innovative processes to recover lithium and other materials. | Sustainability, reduced resource dependency. | Scalability and commercial viability. | Lower environmental impact, circular economy benefits. |

| Fast-Charging Solutions | Technologies reducing charge time to minutes. | Convenience, greater adoption rates. | Battery lifespan concerns with rapid charge. | Increased user satisfaction, expanded market reach. |

| Battery Management Systems (BMS) | Advanced algorithms for optimal battery health. | Extended battery life, enhanced performance. | Integration complexities, software reliability. | Improved total cost of ownership for electric vehicles. |

| Lithium-Sulfur Batteries | Use of sulfur to enhance energy capacity. | Higher energy density, lightweight materials. | Cycle stability issues, commercialization hurdles. | Potentially revolutionary for electric vehicle ranges. |

Related Posts

-

Understanding Automobile Start Lithium Battery Benefits and Efficiency?

-

Top 5 Benefits of Using Automobile Start Lithium Batteries for Your Vehicle

-

2025 How to Choose the Best Automobile Start Lithium Battery for Your Vehicle

-

How to Choose the Right Lithium Battery for Your Automobile?

-

Future Trends in 2025 for the Best 48v Forklift Battery and Innovative Solutions for Sustainability

-

7 Essential Benefits of the Best Lifepo4 Energy Storage Battery for Global Buyers